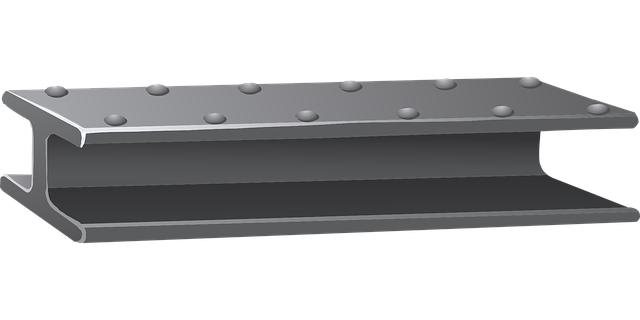

Glue Laminated Beams (GLBs) and Engineered Wood Beams (EWBs) offer modern construction alternatives. GLBs, formed by gluing layers of lumber, provide superior strength and rigidity for heavy load-bearing structures. EWBs, created using advanced manufacturing, offer improved dimensional stability and customizable designs for complex architectural projects. Choosing between them depends on structural requirements, with GLBs ideal for specific applications and EWBs catering to versatile designs while cost-effectively replacing traditional lumber.

“Unleash the power of glue laminated beams with insights from top contractors! This comprehensive guide reveals the secrets behind this innovative construction method, offering a competitive edge in modern building practices. From understanding the basic structure and advantages to choosing the right lumber and design considerations, we demystify effective beam utilization. Learn about installation tips ensuring strength and longevity, plus a cost analysis between glue laminated and traditional engineered wood beams. Optimize your projects with these insider secrets.”

- Understanding Glue Laminated Beams: Basic Structure & Advantages

- Choosing the Right Lumber: Key Factors for Optimal Glue Lamination

- Design and Engineering Considerations for Efficient Beam Utilization

- Application Secrets: Where and How to Effectively Use Glue Laminated Beams

- Installation Tips: Ensuring Strength and Longevity in Construction

- Cost Analysis: Engineered Wood vs. Traditional Beams

Understanding Glue Laminated Beams: Basic Structure & Advantages

Glue Laminated Beams, often referred to as engineered wood beams, offer a modern alternative to traditional lumber choices. Unlike Glue Laminated Beams vs. Engineered Wood: Structural Comparison, where each has unique advantages and applications, understanding their basic structures is crucial.

What are Engineered Wood Beams? Benefits Explained, they are created by gluing together multiple layers of dimensional lumber, forming a strong, solid beam. This process enhances strength and durability, enabling them to withstand heavy loads, especially in structural applications. Advantages of Glue Laminating for Beam Construction include improved dimensional stability, reduced warping, and increased load-bearing capacity compared to traditional wooden joists. Their versatility allows for complex architectural designs, making them a preferred choice in modern construction. Visiting us at 18 Clifton St, Unadilla, NY 13849 anytime, you can explore these innovations firsthand, as we specialize in providing top-quality engineering solutions.

Choosing the Right Lumber: Key Factors for Optimal Glue Lamination

Choosing the right lumber for glue laminated beams is crucial, as it directly impacts structural integrity and long-term performance. When comparing glue laminated beams vs. engineered wood beams, several key factors come into play.

Optimal glue lamination involves selecting high-quality timber with consistent moisture content. Unlike traditional wooden joists, glue laminated beams are created by gluing together multiple layers of lumber, enhancing strength and stability. This process allows for larger span capabilities and better resistance to warping or splitting. Factors like the type and quality of glues used, as well as the precision in laminating, contribute to the overall strength and durability of glued structural components. Understanding these intricacies can help contractors make informed decisions when selecting the best option for their projects. Give us a call at (607) 369-9341 for expert guidance on choosing between engineered wood and laminated beams.

Design and Engineering Considerations for Efficient Beam Utilization

When it comes to design and engineering considerations for efficient beam utilization, contractors have a crucial decision to make: choosing between Glue Laminated Beams (GLB) and Engineered Wood Beams (EWB). A glue laminated beam vs. engineered wood: structural comparison reveals distinct advantages in terms of strength and durability. GLBs, created by gluing multiple layers of lumber together, offer superior load-bearing capabilities due to their inherent rigidity and the powerful bonds formed by modern glues. This construction method is particularly beneficial for projects requiring longevity and robust structural integrity.

On the other hand, EWBs are engineered using advanced manufacturing techniques, combining multiple wood strands or veneers with adhesives to form a strong, composite material. They provide what are engineered wood beams? benefits explained, such as improved dimensional stability, reduced weight compared to traditional lumber, and enhanced resistance to warping and splitting. When considering how do glue laminated beams differ from wooden joists?, it’s essential to understand that GLBs are designed for specific structural applications, while EWBs offer versatility in architectural designs due to their customizable dimensions and aesthetic appeal. For a cost-effective solution without compromising quality, many contractors opt for engineered wood beams vs traditional lumber choices. Give us a call at (607) 369-9341 to discuss your project needs further.

Application Secrets: Where and How to Effectively Use Glue Laminated Beams

Glue Laminated Beams vs Engineered Wood: A Structural Comparison

When it comes to structural integrity and design versatility, both Glue Laminated Beams (GLB) and Engineered Wood Beams (EWB) have their unique strengths. Understanding where each excels is crucial for making informed decisions in construction projects. In terms of what are engineered wood beams? and their benefits explained, EWBs offer superior strength-to-weight ratio and dimensional stability due to their sophisticated manufacturing process. They are ideal for complex architectural designs where precision and consistency are paramount.

On the other hand, GLBs stand out in applications requiring extreme strength and durability, such as heavy load-bearing structures. How do glue laminated beams differ from wooden joists? Their construction involves gluing together multiple laminations of wood veneers, creating a single component that surpasses traditional joinery in strength and longevity. This advanced technique enables GLBs to withstand significant structural stresses, making them a preferred choice for modern construction methods. Advantages of glue laminating for beam construction include enhanced stiffness, reduced weight, and improved resistance to environmental factors like moisture. Visit us at 18 Clifton St, Unadilla, NY 13849 anytime to learn more about these innovative building solutions.

Installation Tips: Ensuring Strength and Longevity in Construction

When installing glue laminated beams, prioritizing strength and longevity is paramount for successful construction projects. Unlike traditional wooden joists, glue laminated beams are engineered through a meticulous process that involves bonding multiple layers of lumber together with high-performance glues. This innovative method enhances structural integrity, making them a superior alternative in various applications. The benefits of glue laminating include increased strength, reduced weight, and improved dimensional stability compared to solid lumber.

For optimal results, consider these installation tips: ensure proper alignment and fastening of beams to prevent shifting, use high-quality glues recommended for structural applications, and follow engineering calculations for load distribution. By adhering to these practices, you’ll harness the full potential of glue laminated beams versus engineered wood, ensuring your construction projects stand the test of time while maintaining exceptional structural integrity. For expert guidance on beam selection and installation, visit us at 18 Clifton St, Unadilla, NY 13849 anytime.

Cost Analysis: Engineered Wood vs. Traditional Beams

When comparing Glue Laminated Beams vs Engineered Wood Beams, a structural analysis reveals distinct advantages. While traditional lumber has long been the go-to choice for beam construction, advancements in engineering have made engineered wood beams a compelling alternative. These innovative structures offer superior strength and durability compared to solid lumber, thanks to their composition of multiple layers of dimensional lumber bonded together with strong, permanent glues.

This glue laminated beam vs engineered wood: structural comparison highlights several key benefits. Engineered wood beams can handle heavier loads than traditional timbers, making them ideal for modern construction techniques demanding increased structural integrity. Their consistent dimensions and superior resistance to warp or rot further enhance their appeal. Moreover, the benefits of using glued laminated timber extend beyond strength; they contribute to environmentally friendly building practices as well. To learn more about these innovative solutions, visit us at 18 Clifton St, Unadilla, NY 13849 anytime.

Top contractors reveal the power of glue laminated beams, showcasing their superior strength-to-weight ratio and environmental benefits over traditional construction methods. By understanding the unique structure, choosing the right lumber, and applying expert design and installation techniques, builders can harness the advantages of these engineered solutions. Whether for structural integrity or cost-effectiveness, glue laminated beams offer a cutting-edge alternative to conventional choices, such as engineered wood beams, ensuring longer-lasting and more sustainable structures.