Cost Guide: Glue Laminated Beams vs. Engineered Wood Beams

This text compares Glue Laminated Beams (GLB) and Engineered Wood Beams (EWB), highlighting their distinct manufacturing processes and advantages. GLB…….

In the realm of construction and engineering, the choice between structural components is a critical decision that can significantly impact project outcomes. Among various options, glue laminated beams and engineered wood beams have emerged as versatile and efficient solutions for building frameworks. This article delves into the intricate details of these two beam types, exploring their unique characteristics, applications, and the ongoing debate regarding their advantages and limitations. By examining “Glue Laminated Beam vs. Engineered Wood Beam,” readers will gain valuable insights into the evolving landscape of construction materials, enabling informed decisions in an industry that demands strength, sustainability, and innovation.

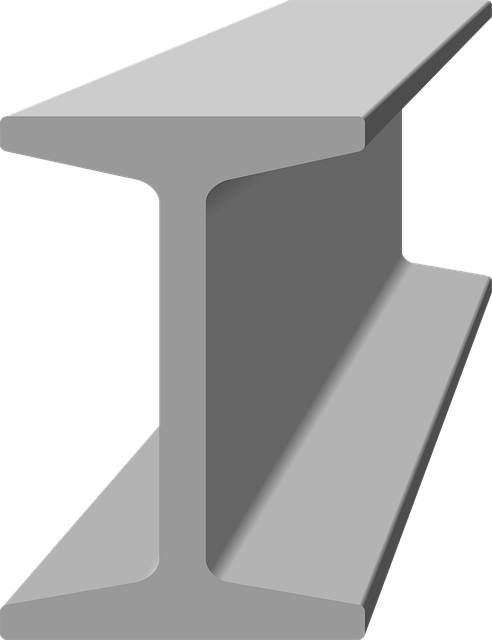

“Glue Laminated Beam” (GLB) and “Engineered Wood Beam” (EWB) represent innovative structural elements engineered from wood, each with distinct construction methods. GLBs are created by laminating multiple thin layers of wood, or plies, together with glue under high pressure. This process results in a beam with exceptional strength-to-weight ratio and dimensional stability. EWBs, on the other hand, are manufactured by gluing together parallel strips of wood, known as lamina, to form a solid core, which is then sandwiched between two outer layers (facings). This design offers both structural integrity and aesthetic appeal.

The concept of engineered wood products has its roots in the late 19th century when inventors sought ways to enhance the strength and durability of natural wood. Over time, advancements in adhesive technology and manufacturing processes led to the development of GLBs and EWBs. These beams have found widespread applications in residential and commercial construction, bridging the gap between traditional timber framing and modern engineering requirements. Their significance lies in offering sustainable, cost-effective alternatives while meeting stringent structural codes.

The global market for glue laminated beams and engineered wood beams is characterized by increasing demand from regions with robust construction sectors. North America, Europe, and Asia-Pacific dominate this landscape due to their advanced manufacturing capabilities and stringent building regulations. For instance, countries like the United States, Canada, and several European nations have embraced EWBs for their versatility and performance in high-rise buildings and wooden structures.

Several key trends are driving the growth of GLBs and EWBs:

Regional differences in climate, building codes, and cultural preferences influence the adoption of GLBs and EWBs:

| Region | Popular Beam Type | Reasons |

|—|—|—|

| North America | Engineered Wood Beams | Abundant forest resources, strict building codes requiring high structural performance, and a preference for wooden structures. |

| Europe | Glue Laminated Beams | Strict environmental regulations promoting sustainable construction, long-standing tradition of timber framing, and advanced manufacturing expertise. |

| Asia-Pacific | Both, with varying preferences | Diverse climate conditions, rapid urbanization, and growing interest in modern architectural designs drive demand for both types. |

The global market for GLBs and EWBs is characterized by:

Manufacturers and investors are drawn to this sector for several reasons:

While initial costs may vary, GLBs and EWBs often prove more economical over their lifespan due to:

Technological breakthroughs have revolutionized the production of GLBs and EWBs:

These advancements have yielded significant benefits:

The future holds promise for:

Key organizations and regulatory bodies influence the development and use of GLBs and EWBs:

Regulatory frameworks play a pivotal role in:

Despite their advantages, GLBs and EWBs face several challenges:

Addressing these issues involves:

Real-world examples highlight the versatility and benefits of GLBs and EWBs:

Case Study 1: GreenSky High-Rise, Seattle, USA

This iconic high-rise residential building utilized advanced EWBs in its structural framework. The project faced challenging site conditions and required a lightweight yet strong solution. EWBs provided the necessary span capabilities, enabling efficient floor systems while adhering to strict green building standards.

Case Study 2: Forest City Development, Toronto, Canada

A mixed-use development project embraced GLBs as part of its sustainable design philosophy. By utilizing these beams, the developers achieved significant cost savings and reduced the building’s carbon footprint due to the rapid renewability of wood sources.

Case Study 3: Traditional Japanese Timber Framing, Kyoto, Japan

The restoration of historic wooden temples in Kyoto showcased the timeless appeal of traditional timber framing, employing GLB techniques. This case highlights the cultural significance and aesthetic value that these beams bring to architectural preservation projects.

The future holds immense potential for:

Keep an eye out for:

To capitalize on these trends, stakeholders should:

“Glue Laminated Beam vs. Engineered Wood Beam” represents a dynamic interplay of technology, sustainability, and construction needs. As the world navigates the complexities of modern architecture and engineering, these beam types continue to shape the built environment. Understanding their intricacies, from historical development to future prospects, is essential for professionals and enthusiasts alike. By embracing technological advancements and addressing challenges head-on, the industry can unlock the full potential of GLBs and EWBs, paving the way for a more sustainable and architecturally rich future.

Q: What are the primary advantages of glue laminated beams over traditional timber framing?

A: GLBs offer superior strength-to-weight ratio, enhanced dimensional stability, and better resistance to environmental factors like moisture and pests. They also provide consistent performance due to precision manufacturing.

Q: Are engineered wood beams more sustainable than steel or concrete?

A: Yes, EWBs are considered more environmentally friendly as they come from renewable wood sources and have a lower carbon footprint during production compared to steel and concrete.

Q: How do GLBs and EWBs address fire safety concerns?

A: While natural wood is flammable, modern treatments and coatings can significantly improve their fire resistance. Strict building codes and appropriate design considerations ensure that these beams meet safety standards.

Q: Can these beam types be used for residential construction?

A: Absolutely! GLBs and EWBs are widely used in residential buildings, offering cost-effective and efficient solutions for various architectural styles and designs.

Q: What is the expected future of these beams in the face of evolving construction technologies?

A: The future looks bright with ongoing advancements in materials science and digital design. We can expect smarter, more sustainable, and customizable beam solutions that will revolutionize construction practices worldwide.

This text compares Glue Laminated Beams (GLB) and Engineered Wood Beams (EWB), highlighting their distinct manufacturing processes and advantages. GLB…….

This section compares Glue Laminated Beams (GLBs) and Engineered Wood Beams (EWBs), highlighting their structural advantages in modern construction. G…….

This text compares Glue Laminated Beams and Engineered Wood Beams for construction, highlighting their manufacturing processes, advantages like enhanc…….

Glue Laminated Beams (GLBs) and Engineered Wood Beams (EWBs) offer modern alternatives to traditional construction. GLBs, stronger and more uniform, h…….

Glue Laminated Beams (GLBs) and Engineered Wood Beams (EWBs) offer distinct structural benefits for modern construction. GLBs, through advanced gluing…….

This text compares Glue Laminated Beams (GLBs) and Engineered Wood Beams (EWBs), highlighting structural strength, cost, and versatility. GLBs, made b…….

Glue laminated beams, created by bonding multiple wood layers with glues, outperform traditional joists in strength and durability. They offer better…….

Glue Laminated Beams (GLB) vs. Engineered Wood Beams (EWB): GLBs use lamination with strong glues to offer superior strength, durability, and load-bea…….

This text compares Glue Laminated Beams (GLBs) and Engineered Wood Beams, highlighting their structural differences and benefits for modern constructi…….

Glue Laminated Beams (GLBs) and Engineered Wood Beams (EWBs) offer modern structural solutions with enhanced strength over traditional lumber. GLBs us…….