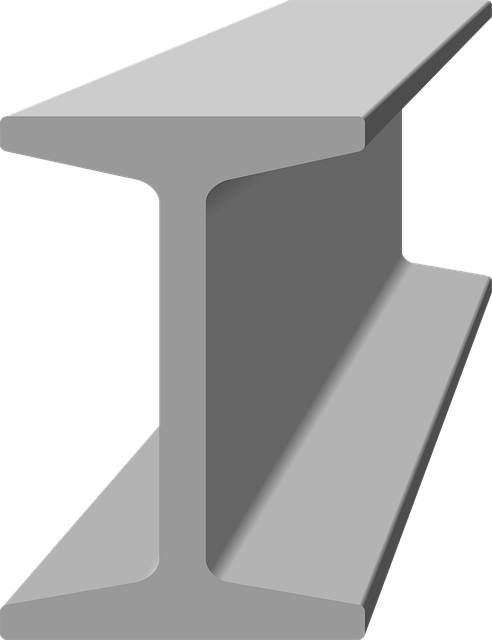

Glue Laminated Beams (GLBs) and Engineered Wood Beams (EWBs) offer modern alternatives to traditional joists, with GLBs using lamination for superior strength and low warping risk, while EWBs employ engineering techniques to optimize material distribution. Key advantages include GLBs' unmatched strength-to-weight ratio, ideal for high-load structures, and EWBs' enhanced versatility and eco-friendliness. Selection depends on project needs, budget, and design preferences; consult experts like unalam.com for detailed insights.

Selecting the right structural solution for your building project is crucial, especially when comparing Glue Laminated Beam and Engineered Wood Beam. This article offers a practical guide on choosing between these two innovative alternatives. We’ll break down their unique features and benefits, highlighting key differences to help you make an informed decision. Whether you’re a professional or a DIY enthusiast, understanding these options is essential for successful construction.

- Understanding Glue Laminated Beams

- Key Differences from Engineered Wood Beams

- Choosing Between Them: A Practical Approach

Understanding Glue Laminated Beams

Glue Laminated Beams, often referred to as GLB or glued timber, represent a modern alternative to traditional Engineered Wood Beams (EWB). While both offer enhanced structural integrity and durability compared to conventional wooden joists, there are distinct differences in their composition and construction methods. Glue Laminated Beam vs. Engineered Wood: understanding these variations is crucial for selecting the optimal material for your building project.

GLBs are created by laminating multiple layers of wood veneer, bonded together with strong adhesives, forming a solid, uniform beam. This process not only enhances strength but also reduces the risk of warping or splitting commonly associated with solid lumber. In contrast, EWBs utilize advanced engineering techniques to combine multiple pieces of wood in a way that optimizes structural performance while minimizing material waste. What sets GLBs apart is their ability to provide unparalleled strength-to-weight ratio, making them ideal for applications where heavy loads and slender designs are required, such as modern high-rise structures or complex architectural plans. To learn more about these innovations, visit unalam.com.

Key Differences from Engineered Wood Beams

When comparing glue laminated beams vs. engineered wood beams, understanding their key differences is essential for making an informed decision in construction projects. While both are structural elements made from timber, they differ significantly in terms of manufacturing processes and performance characteristics.

Glue Laminated Beams vs. Engineered Wood: In the structural comparison, glue laminated beams excel due to advanced lamination techniques that fuse multiple layers of wood with high-performance glues. This results in superior strength, stiffness, and dimensional stability compared to traditional wooden joists. In contrast, engineered wood beams are designed by computer models to optimize material distribution, addressing specific load requirements. They offer enhanced structural integrity, particularly for complex architectural designs, and can be tailored to withstand heavy loads efficiently. Factors like cost, availability, and project-specific needs guide the selection between these two innovative timber solutions. Visit us at unalam.com anytime for expert insights on choosing the right beam type for your construction venture.

Choosing Between Them: A Practical Approach

Choosing between Glue Laminated Beams and Engineered Wood Beams involves understanding their structural comparisons. Glue Laminated Beams vs. Engineered Wood: both offer unique advantages, but differ significantly in terms of construction and properties. Glue Laminated Beams, as the name suggests, involve laminating multiple layers of wood with strong adhesives, creating a robust structural component. This process enhances strength and dimensional stability, making them ideal for heavy-load applications.

On the other hand, Engineered Wood Beams are designed using advanced engineering techniques, combining wood fibers or veneers with adhesives to create composite materials. These engineered solutions often exhibit superior strength-to-weight ratios, enhanced resistance to environmental factors, and consistent performance. When considering either option, it’s crucial to evaluate factors such as structural requirements, project budget, and design preferences. For instance, while Glue Laminated Beams may offer cost advantages, Engineered Wood Beams can provide better versatility and eco-friendliness, especially in modern construction applications. To make an informed decision, consider consulting experts or exploring resources like unalam.com for detailed insights into these innovative building materials.

When selecting between a glue laminated beam and an engineered wood beam, consider their unique attributes. Glue laminated beams offer superior strength and durability due to their multi-layer construction and strong bond, making them ideal for heavy-load applications. Engineered wood beams, on the other hand, provide cost-effectiveness and versatility with various design options, suitable for lighter structural needs. The choice depends on your project’s specific requirements, ensuring you pick the most efficient and appropriate material, whether it’s a glue laminated beam or an engineered wood beam.